OUR HERITAGE

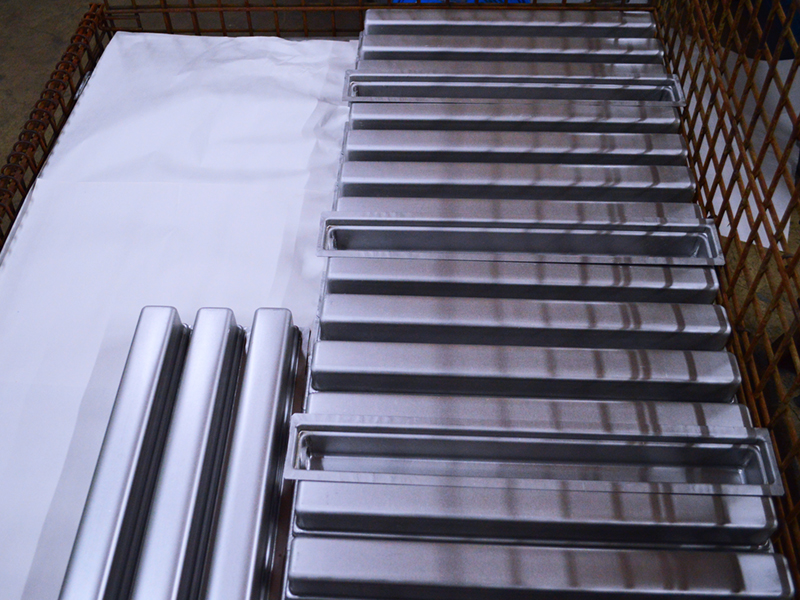

We deliver manufacturing excellence. Since 1962, our technical and manufacturing expertise has helped numerous companies in various industries, increase production efficiency, and product reliability.

WHAT WE DO

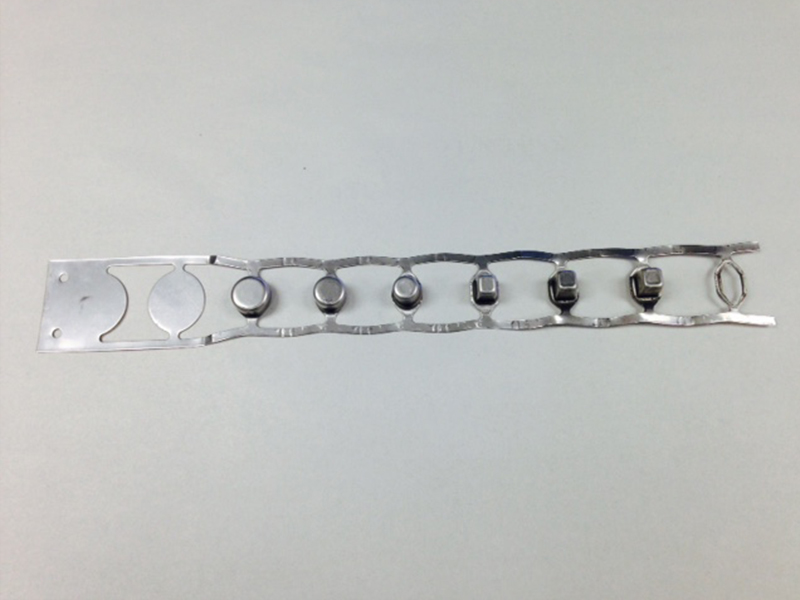

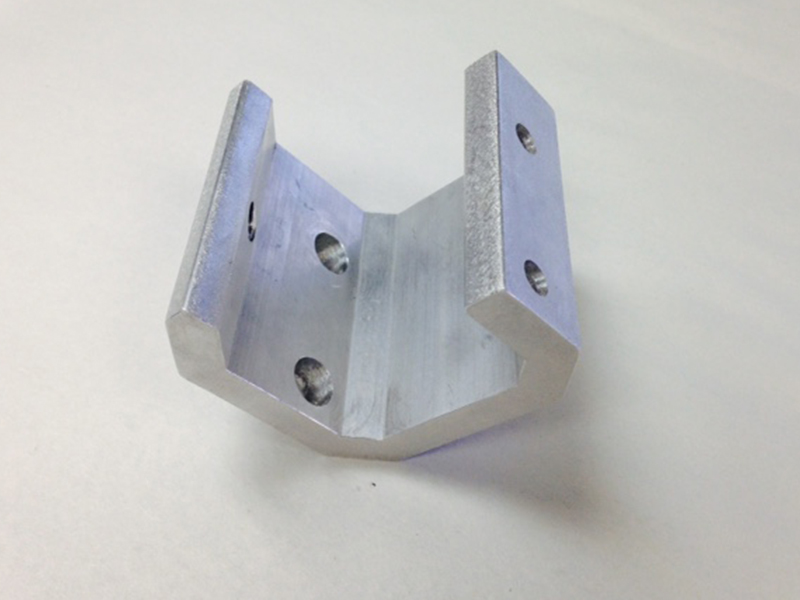

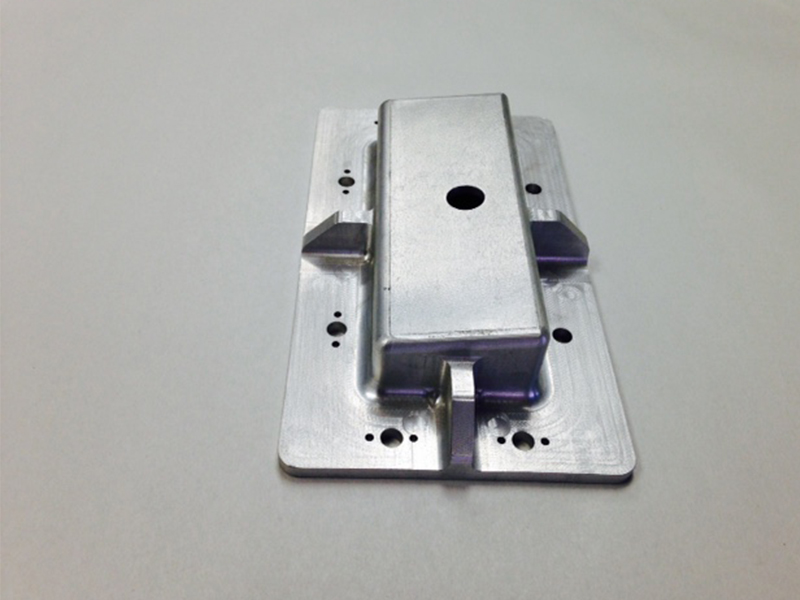

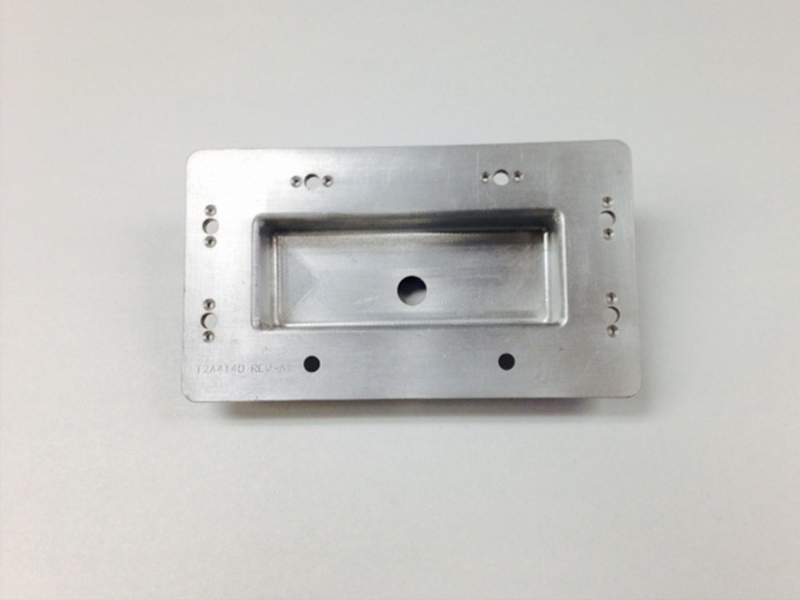

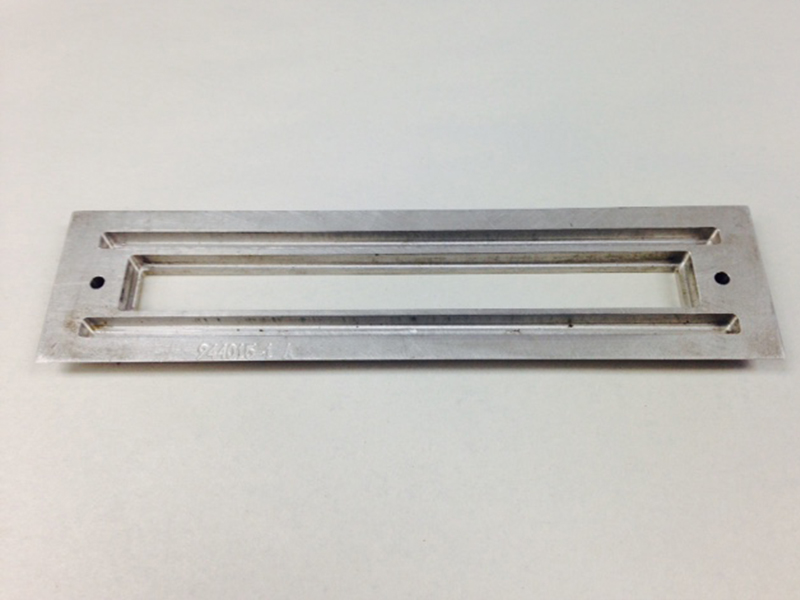

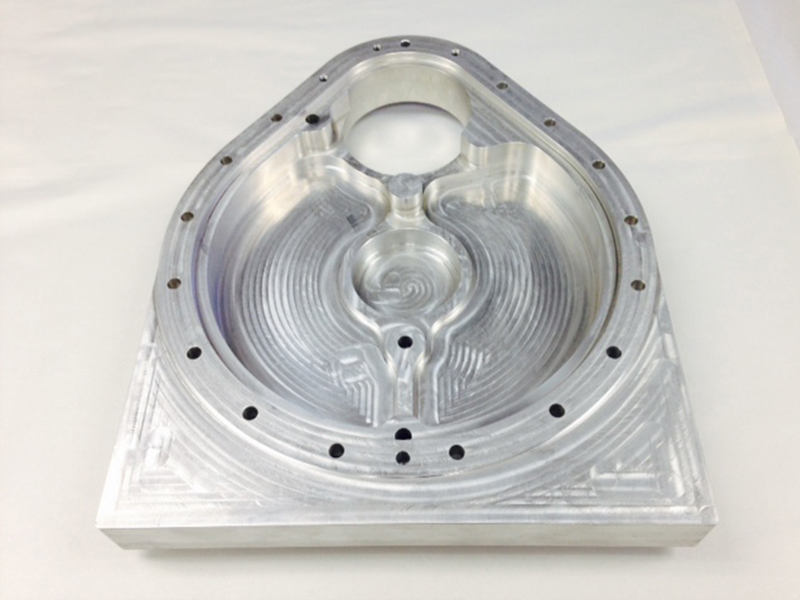

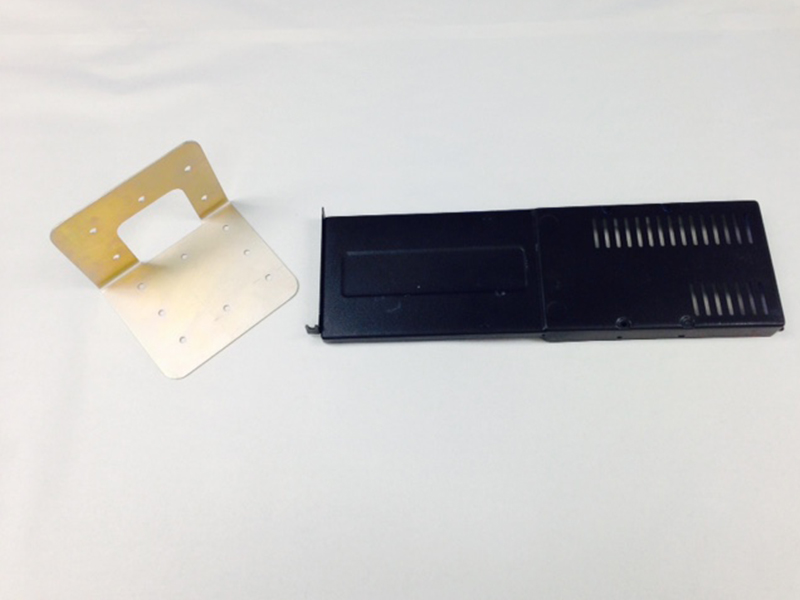

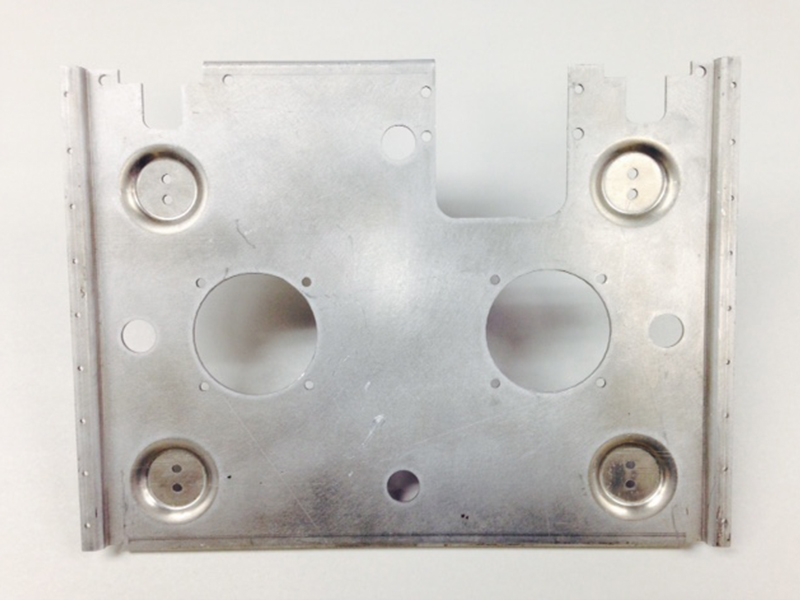

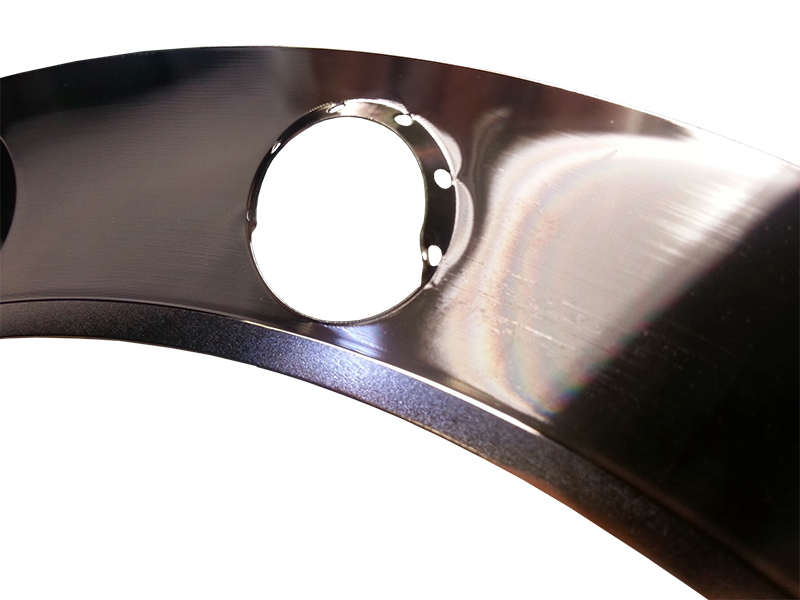

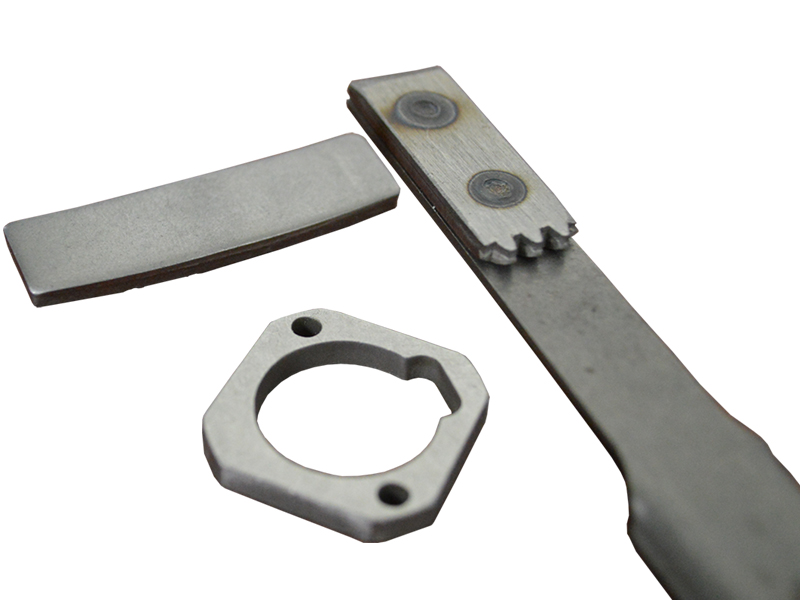

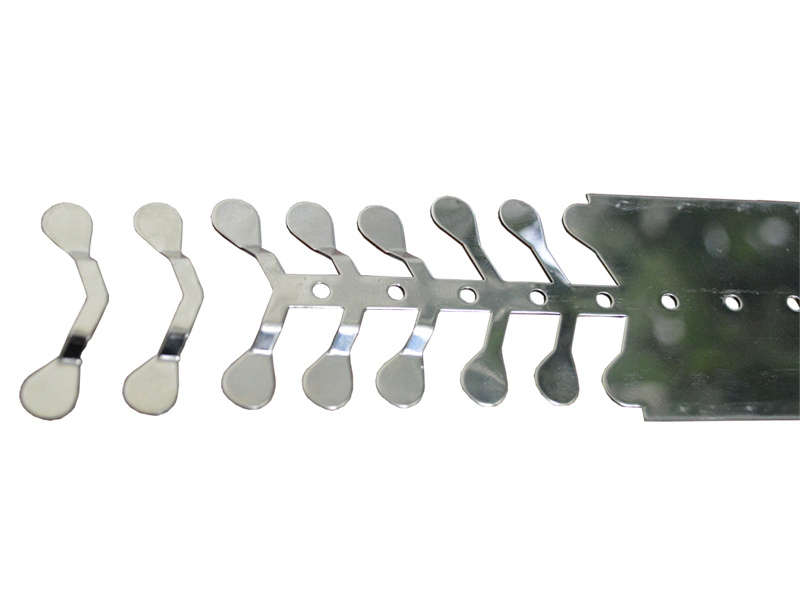

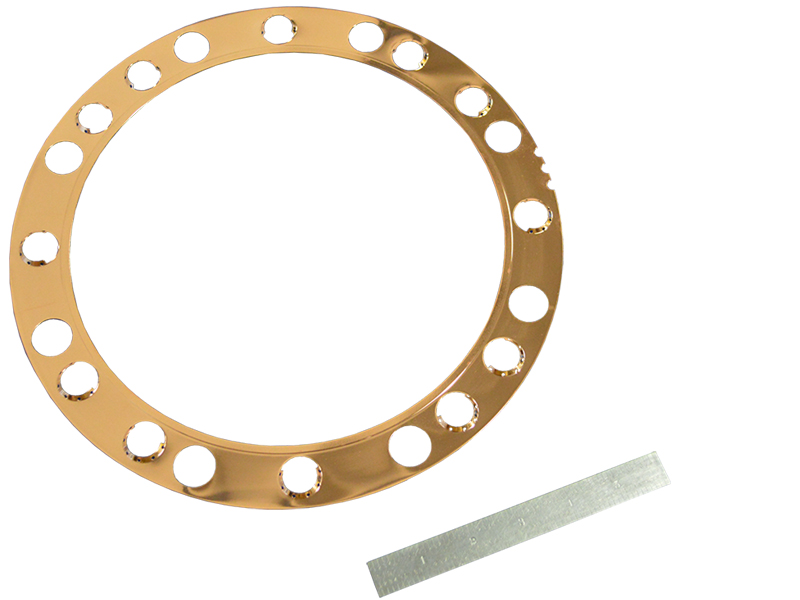

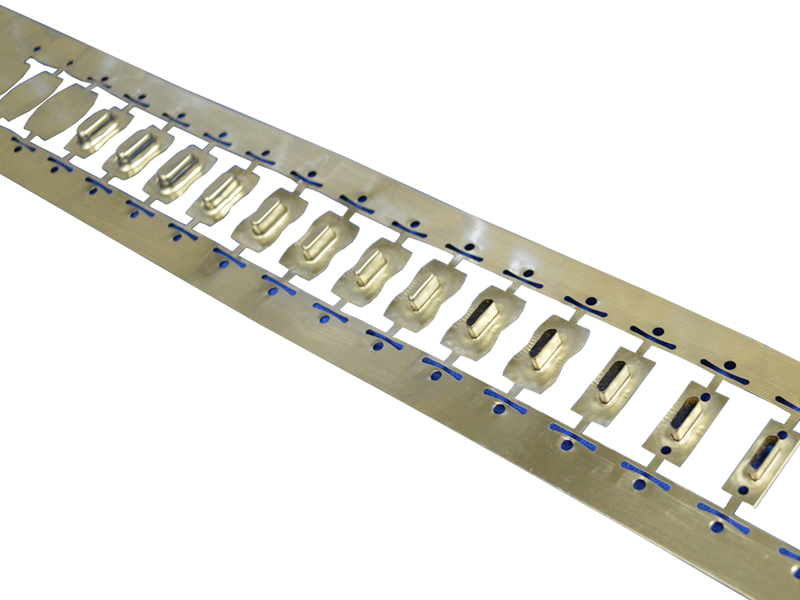

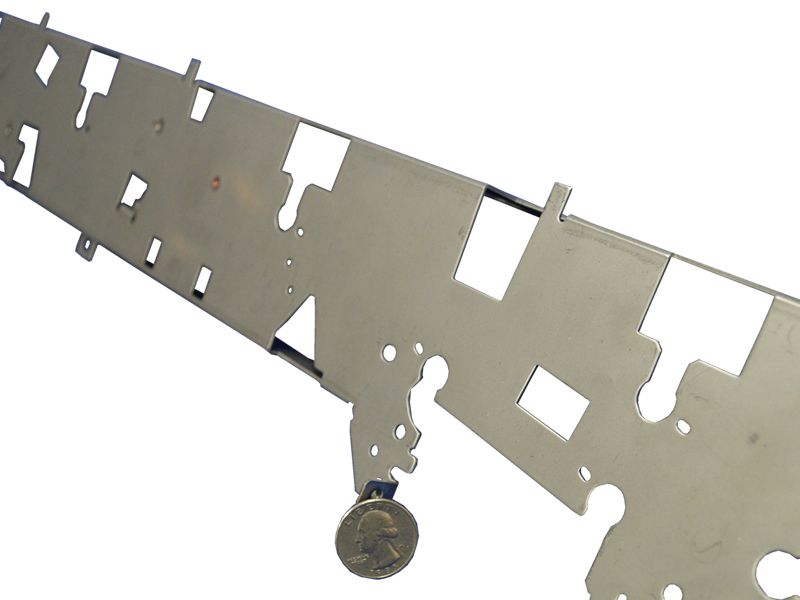

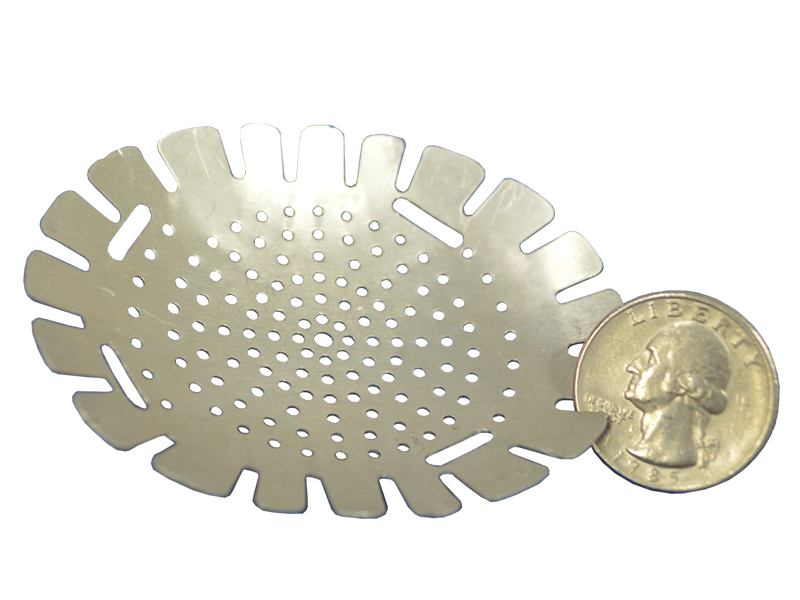

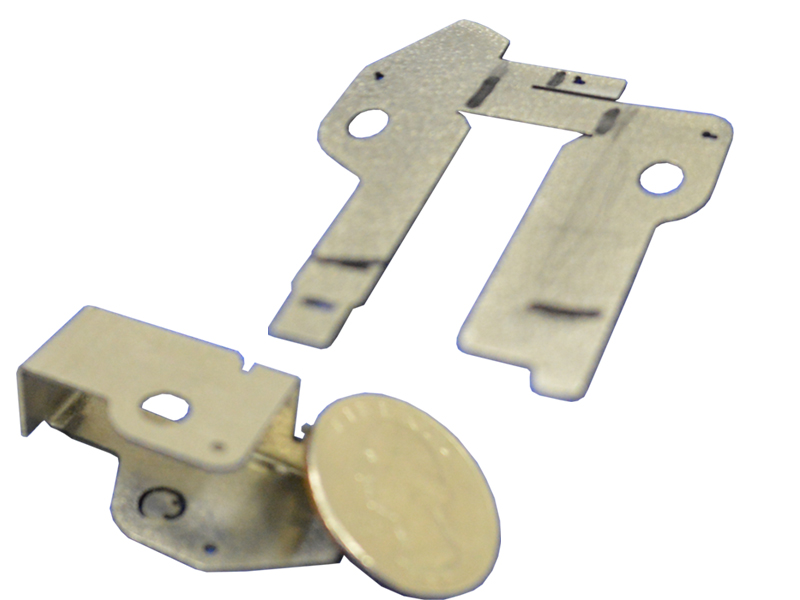

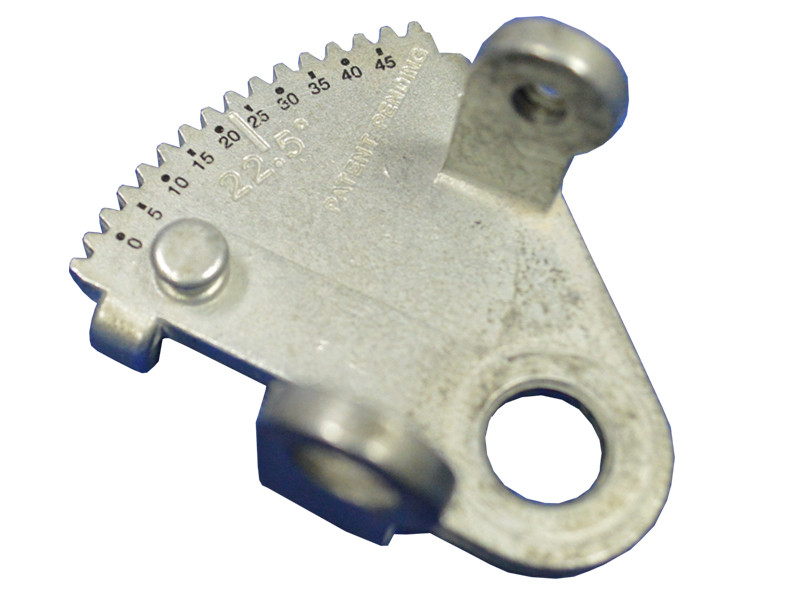

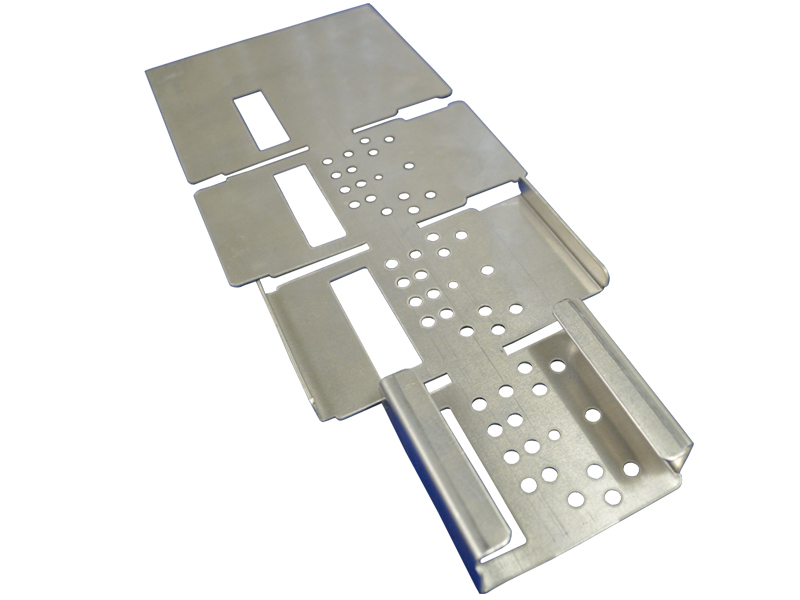

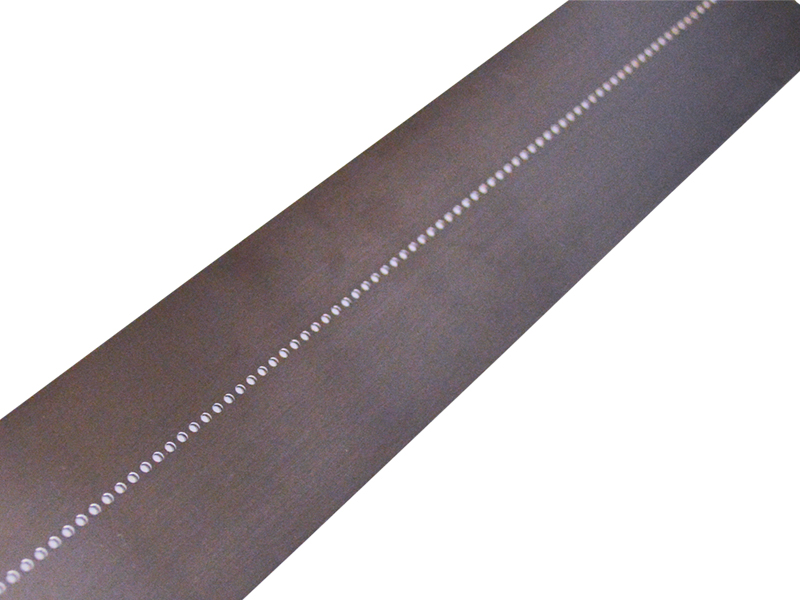

We help transform design concepts into reality. Clients rely on our expertise in stamping, die making, water jet cutting, CNC press brakes, and CNC machining.

WHO WE SERVE

For over 50-years globally recognized companies in the medical, aerospace, industrial, and transportations industries along with start-ups have relied on Crenshaw’s expertise to deliver quality products.