Since 1962, Crenshaw’s technical and manufacturing expertise, combined with its commitment to quality, innovation, collaboration, and continuous improvement and investment in technology, have made it a trusted partner for companies across some of the most demanding end markets.

Founded in 1962, Crenshaw is more than a job shop, we’re a partner in design, manufacturing, and problem solving. Many of our team members have been with us for decades, giving our customers access to unparalleled knowledge, continuity, and craftsmanship.

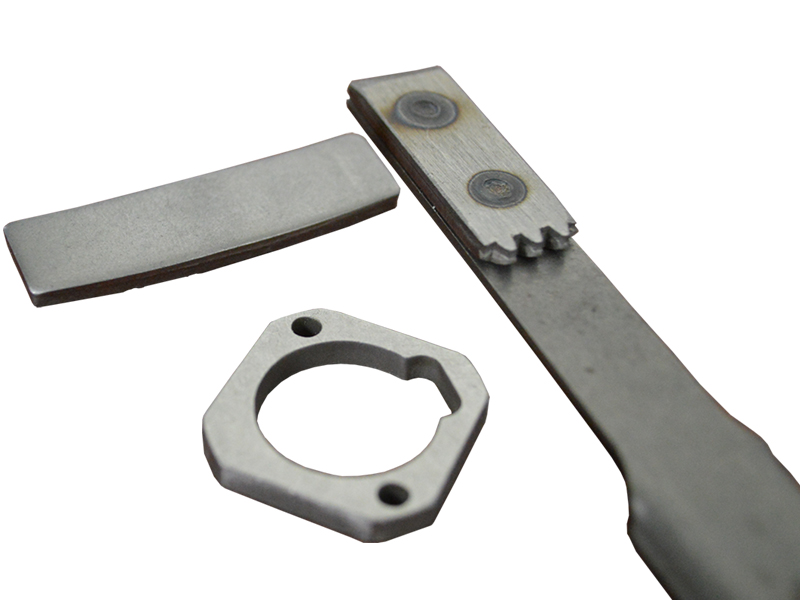

We specialize in solving tough manufacturing challenges through in-house tooling, flexible processes, and innovation that goes beyond conventional fabrication.

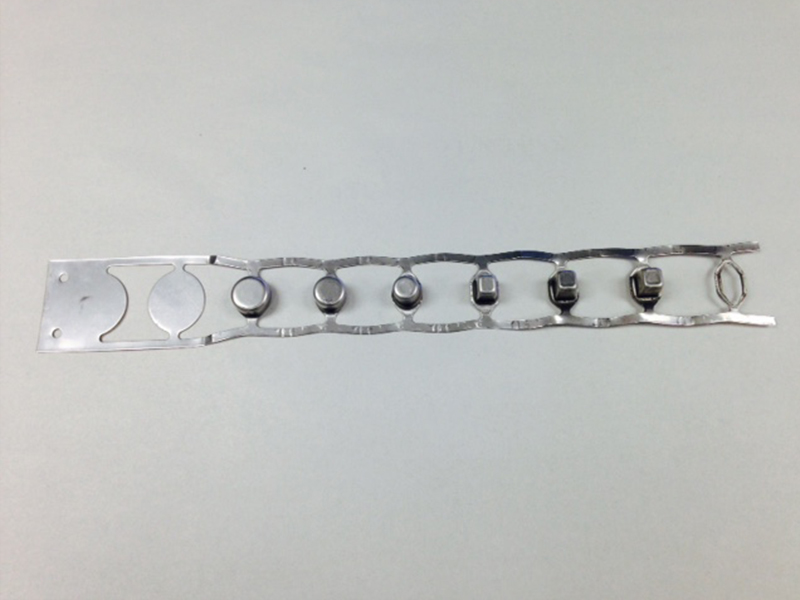

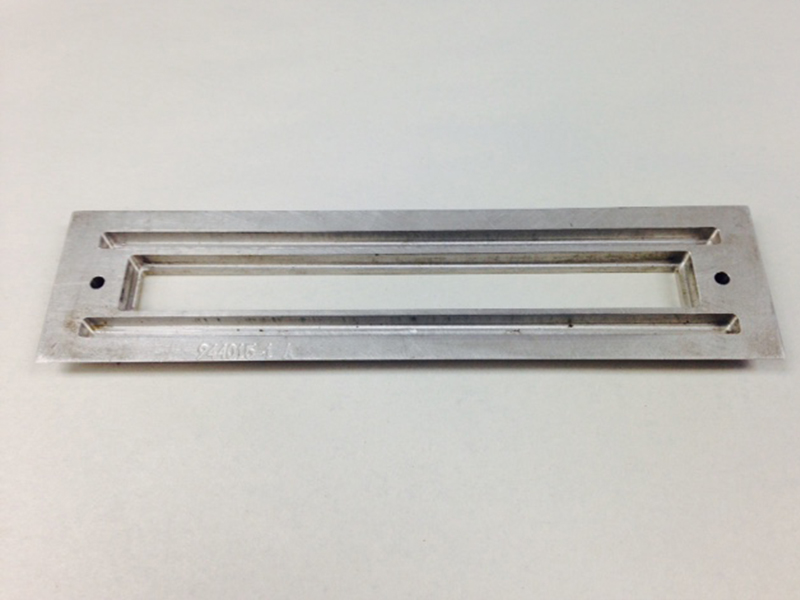

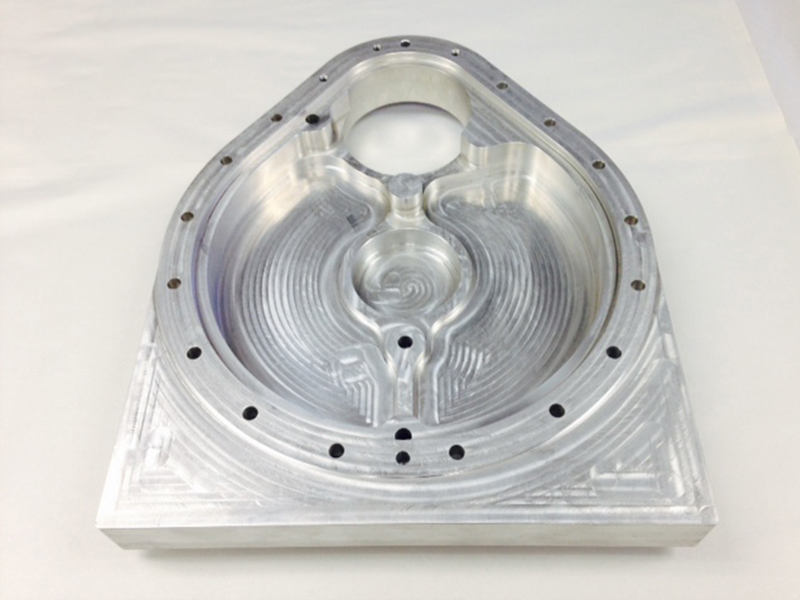

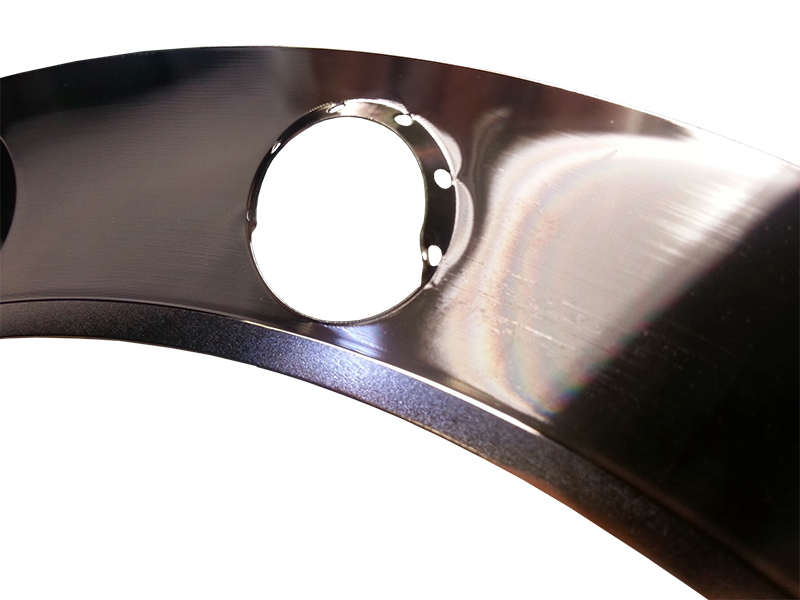

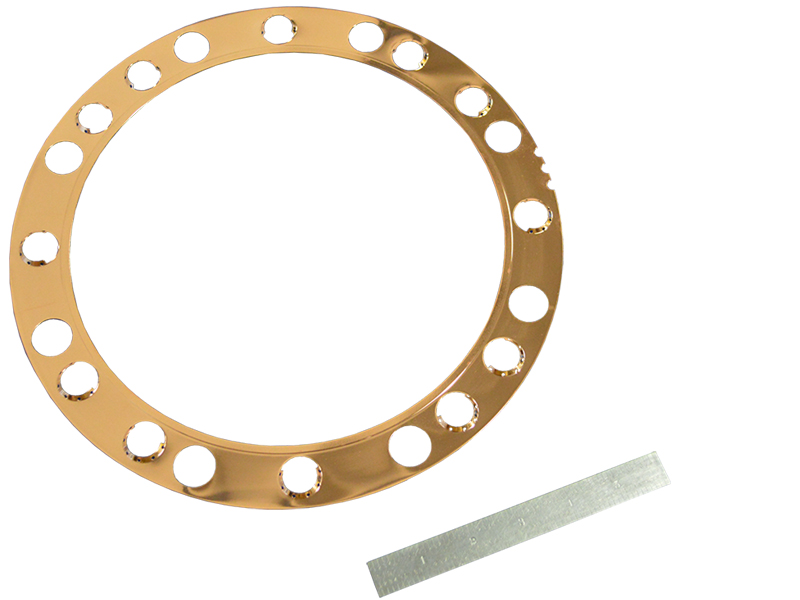

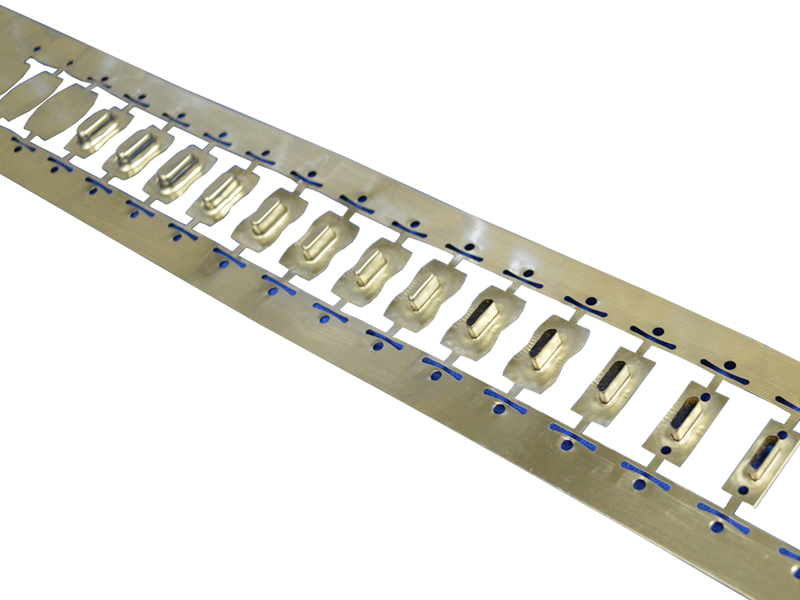

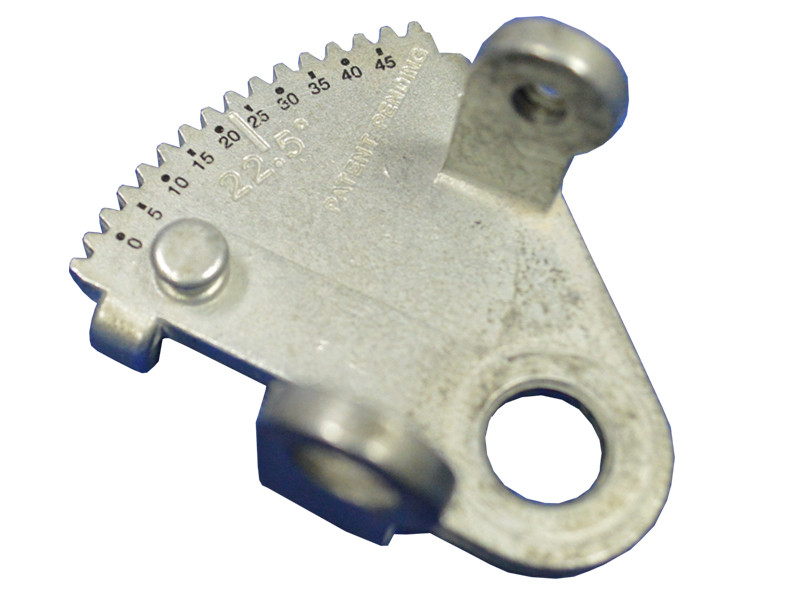

Aerospace Hardware • Medical Device Hardware • Deep Draw

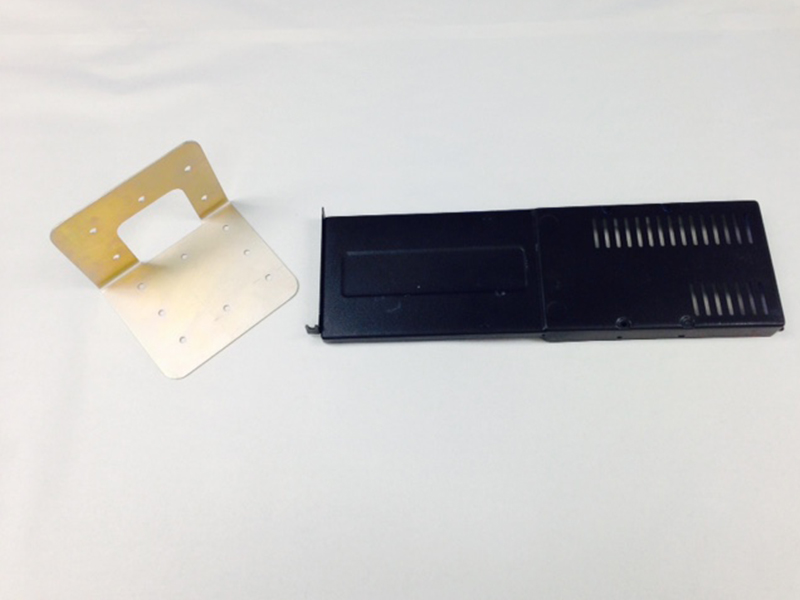

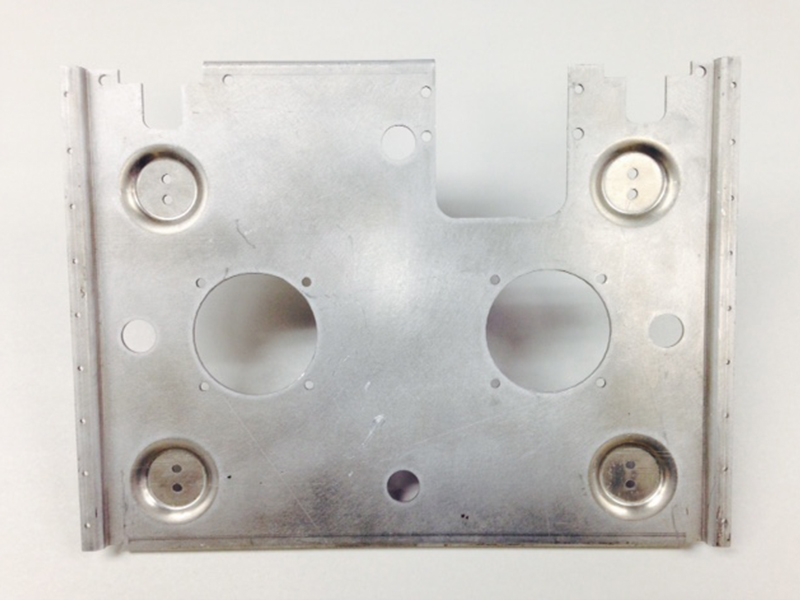

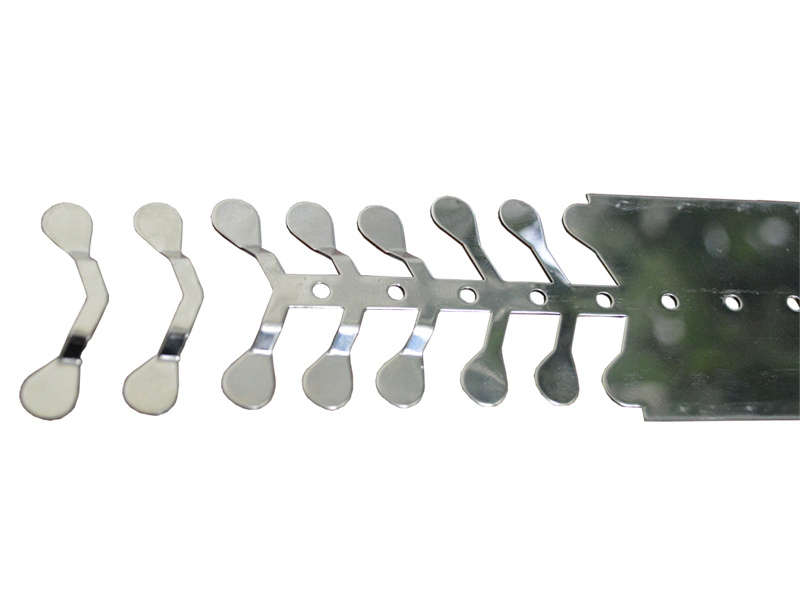

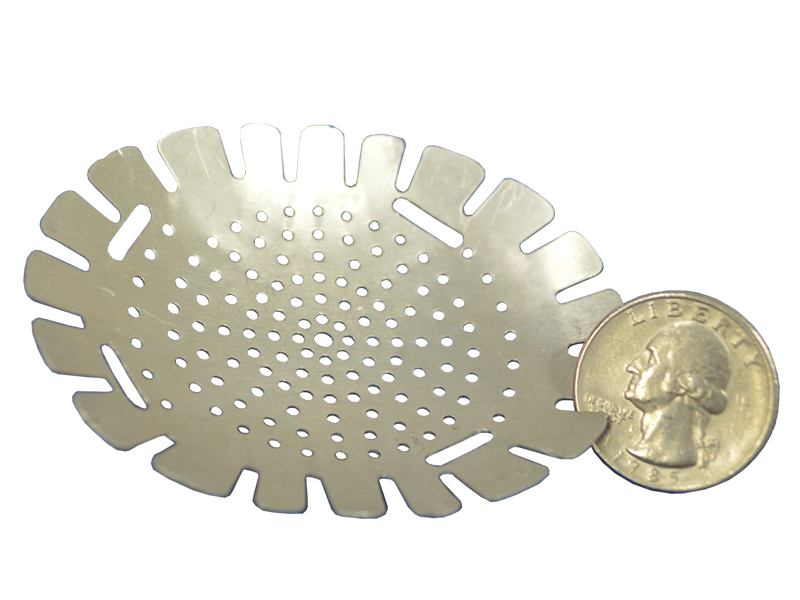

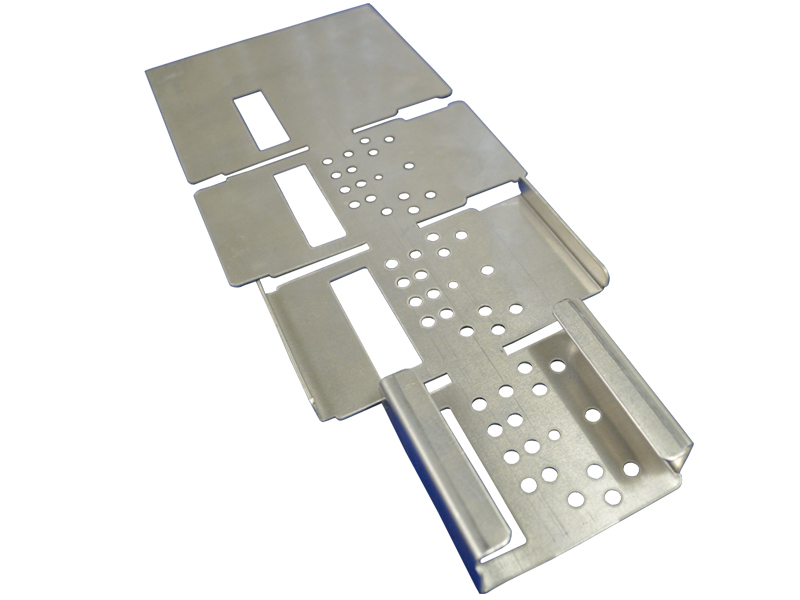

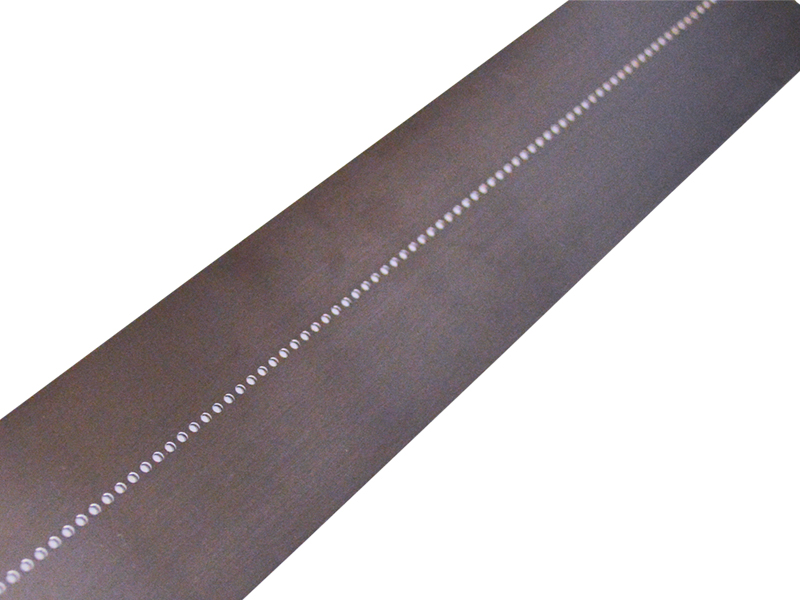

Automotive & Industrial Gaskets • Medical Device Chassis • High Volume Stampings

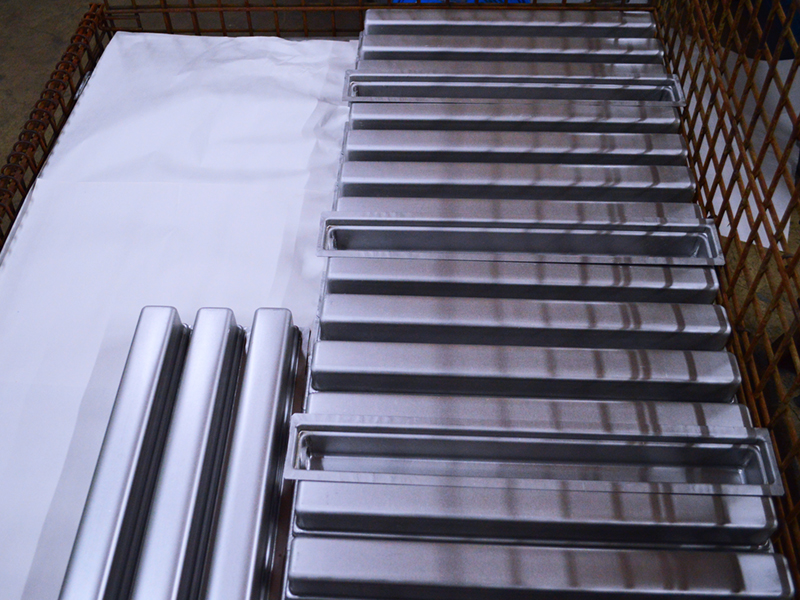

Presses up to 400 Tons • Deep Drawing to 4 Inches • High Speed Methods • Coining

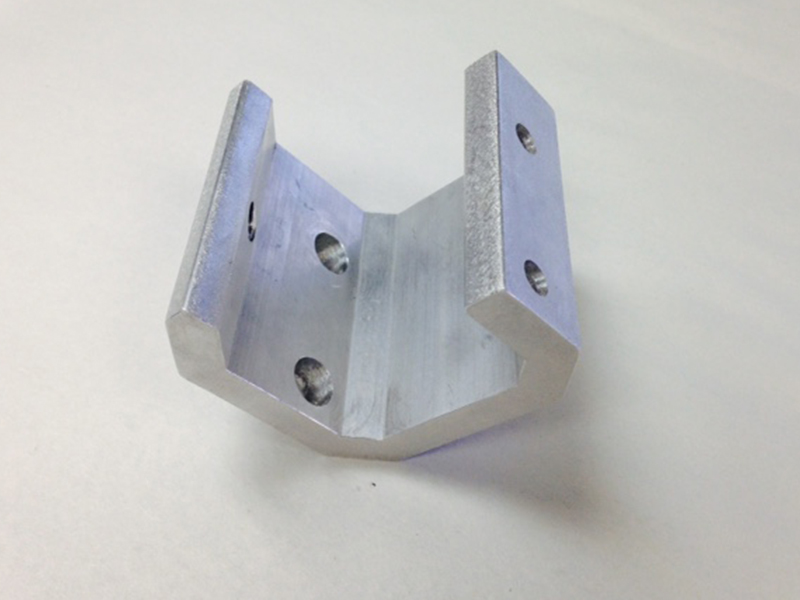

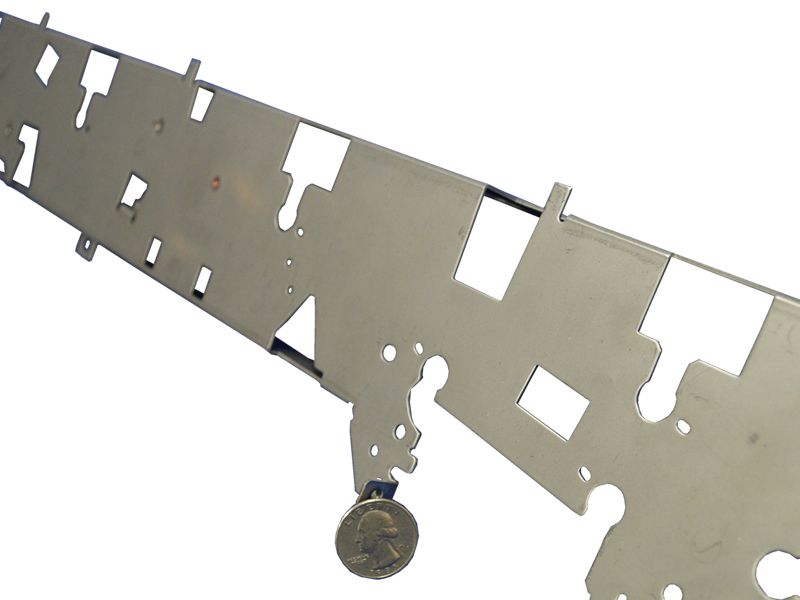

Compound Forming • Waterjet Cutting (72″ x 144″) • Counter Sinking & Spot Welding • Sawing & Cut-Offs

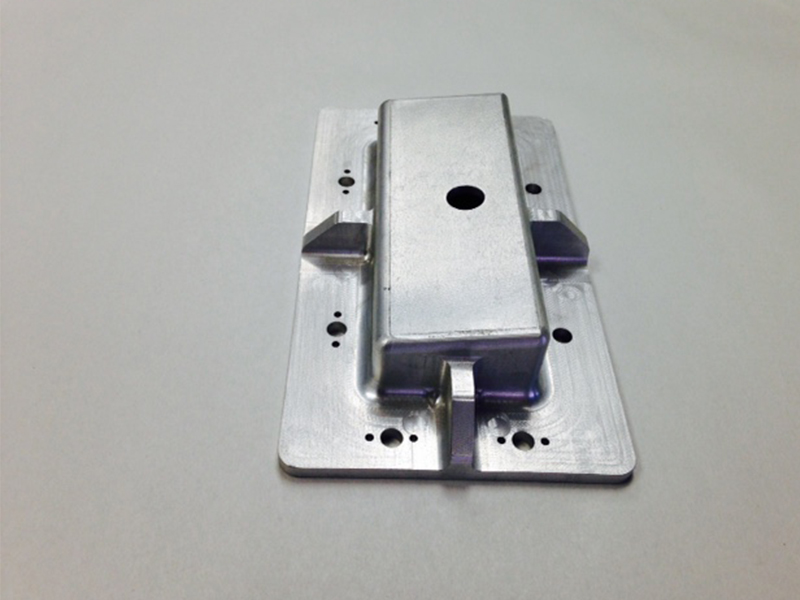

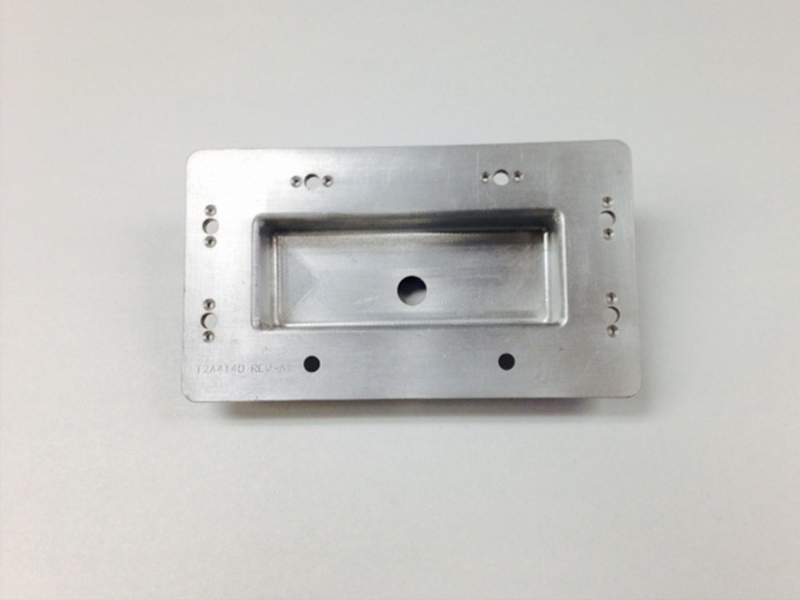

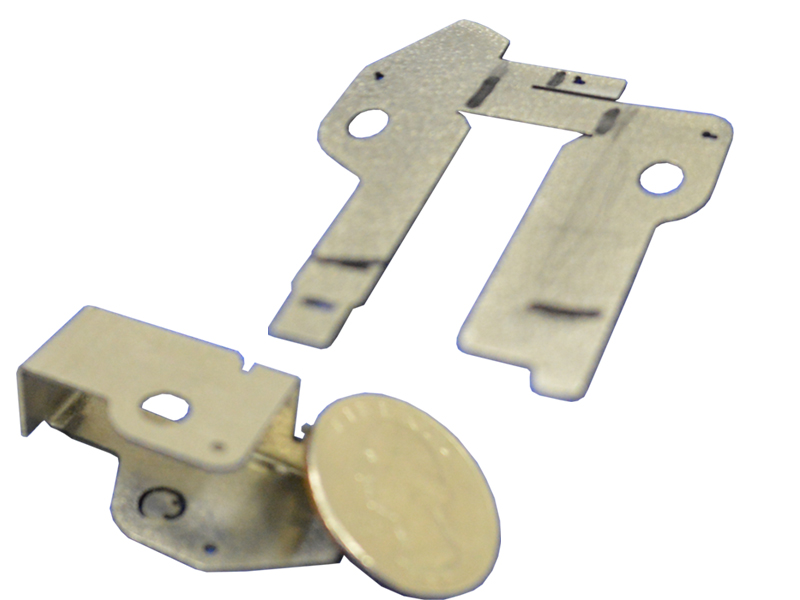

Drilling & Tapping • CNC Maching (40″ x 20″) • Hardware Insertion • Sub-Assemblies • Assemblies & More!

Medical device manufacturers rely on Crenshaw to accurately meet stringent specifications and compliance with quality systems.

From hollow ball bearings to inconel fasteners, Crenshaw has helped aerospace industry leaders lead the way in stamping and forming innovation.

Many Industrial customers have relied upon Crenshaw Die and Manufacturing to deliver quality products to ensure their product’s reliability.

OEM and aftermarket parts for transportation markets, including locomotive, truck, and construction equipment.

By having highly skilled die making capability, Crenshaw has what it takes to ensure that your stamped metal parts become reality.

Technical expertise, imagination, and innovation combined with manufacturing knowledge leads to cost savings and greater efficiency.